Boat Hull Design

Boat hull design refers to the engineering process of defining the dimensions, spacing, and fabrication preparation of the boat structural members that form the shell and load-bearing structure of a vessel. In a strict technical context, hull design is not only about hydrodynamic hull shaping — it specifically involves performing scantling calculations according to established maritime standards to ensure structural integrity and manufacturability.

A complete boat structural design workflow generally includes the following stages:

1. Selecting the Applicable Rules or Standards

The first step of boat design is to determine which rule system or regulatory standard will govern the structural calculation. Commonly used standards include:

- ISO 12215 – Required for CE marking of small craft within the EU market under the Recreational Craft Directive (RCD). Primarily applied to recreational boats and pleasure craft below 24 meters.

- DNV High-Speed and Light Craft Rules

- ABS Rules for Building and Classing High Speed Craft – Notices and General Information

- BV NR396 — Rules for the Classification of High Speed Craft

- CCS Rules for Construction and Classification of Yachts

- Other national or classification society standards – Depending on the flag state or owner’s requirements.

Although these rules follow similar load and safety principles, each introduces subtle differences in formula coefficients, safety factors, and documentation formats. The rule selection directly affects the boat hull design and scantling calculation approach.

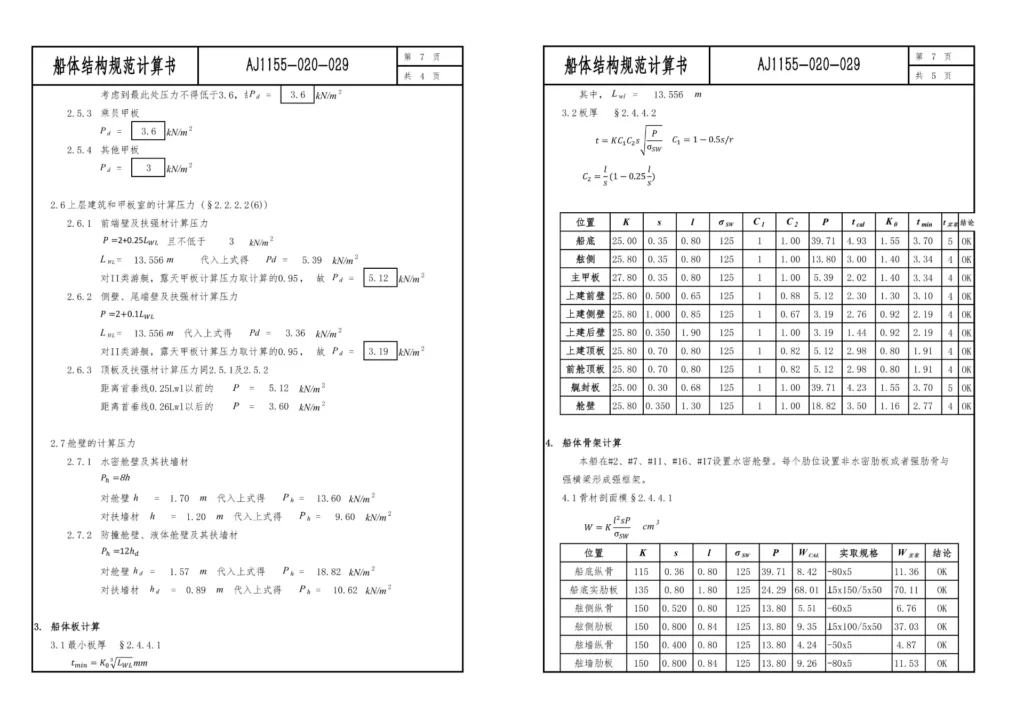

2. Performing Scantling Calculations

Once the standard is selected, scantling calculations are carried out according to the load cases and structural formulas provided in the rule. This phase determines key parameters such as:

- Minimum plating thickness

- Frame and stiffener spacing

- Section modulus for longitudinals, girders, and bulkhead stiffeners

- Reinforcement around openings and local load points

- Additional strengthening for slamming areas, deck landings, and engine foundations

At this stage, the boat structural members begin to take on solid engineering dimensions, forming a rule-compliant structural basis rather than a conceptual design.

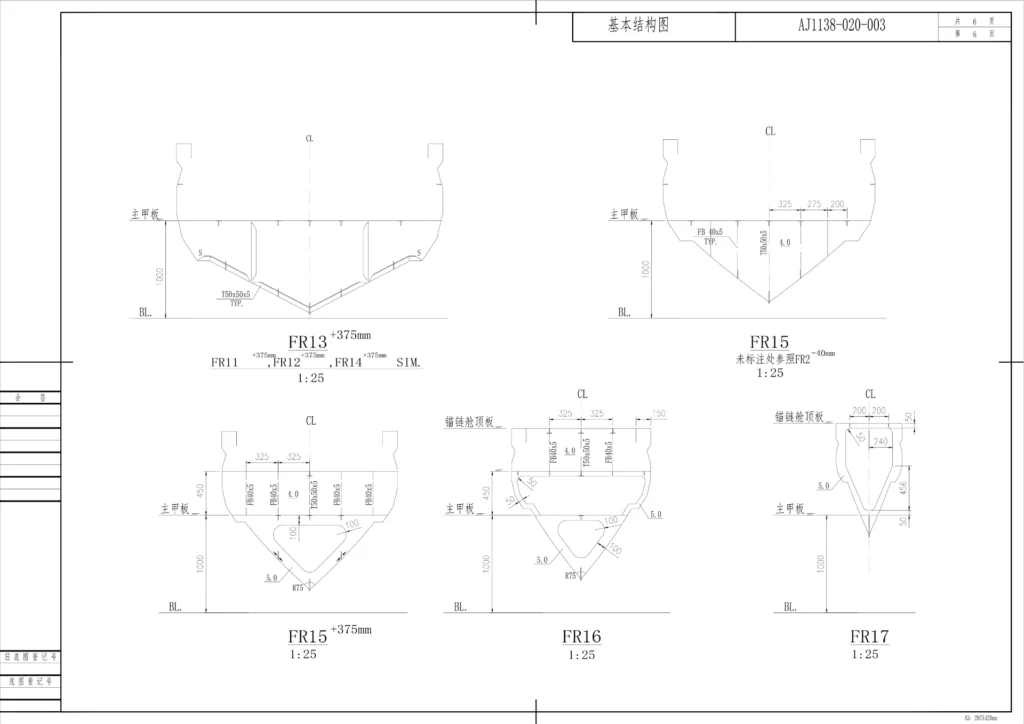

3. Structural Layout Based on General Arrangement

Once the scantling values are finalized, structural members are laid out according to the General Arrangement (GA) of the boat. Frames, longitudinals, bulkheads, and structural decks must be positioned in coordination with:

- Equipment spacing and service access

- Tank arrangement and machinery placement

- Passageways, accommodation layout, and hatch openings

The resulting drawings form the basis of classification submission or owner review.

✅ Summary — Class Approval / Detailed Design Stage

The above steps constitute the approval design stage, commonly known as detailed design or class approval design. The deliverables at this stage include scantling reports and 2D/3D structural plans ready for submission to a classification society or CE/RCD assessment body.

4. Transition to Fabrication — Shop Drawing Generation

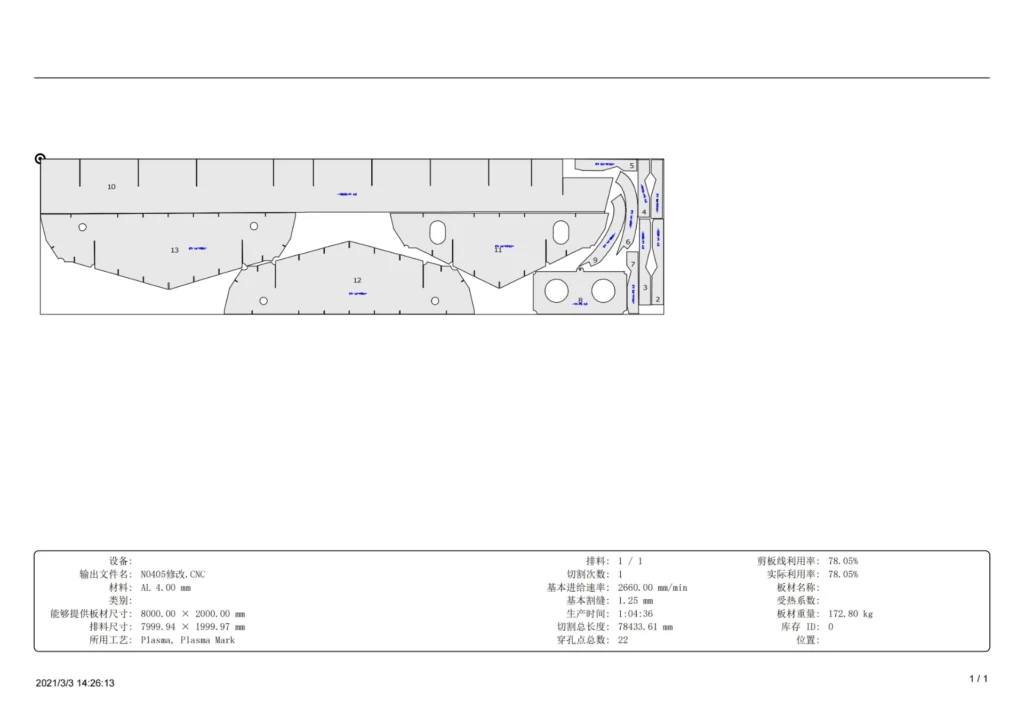

For metal hull boats, after approval drawings are validated, the project enters the production design phase. In this stage, boat hull design shifts from compliance engineering to fabrication detailing.

Using tools such as Rhino, ShipConstructor, AutoCAD, Tekla, or dedicated nesting software, engineers generate:

- Plate development and surface unfolding

- Nesting layouts optimized according to standard steel/aluminum plate sizes

- CNC cutting files for laser or plasma cutting machines

- Part numbering, edge bevel preparation, alignment marks, and assembly references

This production-oriented phase is also called shop drawing generation, where the structural model is transformed into cut-ready digital files to minimize manual fitting work in the shipyard.

Conclusion

From regulatory-compliant scantling calculation to CNC-based shop drawing preparation, boat hull design is a complete engineering workflow that ensures safety, cost efficiency, and fabrication accuracy. Understanding the transition from class approval design to production design is essential for seamless communication between naval architects, CE certification bodies, and metal boat shipyards.