Boat Design

3 Boat Design Stage

The boat design process is typically divided into three main stages:

- Concept Design (Basic Design)

- Detailed Design (Approval Design)

- Production Design (Shop Drawings)

These stages are interconnected and may overlap to some extent. Following this systematic design process usually leads to optimal results in small boat design.

If you want to learn more about the general concept and history of boat design, you can also refer to Wikipedia’s boat design entry.

Concept Design

The boat design journey usually begins with the Concept Design phase, sometimes referred to as Basic Design. At this stage, the fundamental parameters of the boat are determined.

Unlike large ship design, where function often takes precedence, small boat design places equal emphasis on both function and appearance—often called Exterior Design. For many clients, the aesthetics of the boat are just as important as its functionality.

Key tasks and deliverables in the Concept Design phase include:

- Boat Exterior Design (3D Rendering)

- Main Dimensions

- General Arrangement Drawing

With these basic parameters established, the boat design company will conduct a feasibility study based on project experience. The most critical deliverable at this stage is the General Arrangement Drawing, which serves as a guide for subsequent design phases and for all engineering disciplines.

Occasionally, client requirements may not be technically feasible, such as:

- Parameters that violate class rules (e.g., an excessively wide beam resulting in an L/B ratio outside class limits)

- New ideas that are technically sound but not covered by existing classification society rules

In such cases, the design team will work closely with the client to find a balance between their requirements and regulatory constraints.

Detailed Design

Once the concept design is finalized (or sometimes slightly before), the process moves into the Detailed Design phase.

In China, this stage is often synonymous with Class Approval Design, whereas in other countries, “detailed design” may refer to the preparation of shop drawings, which can lead to some confusion.

During the Detailed Design phase, the boat design company prepares a comprehensive set of technical documents required for classification society approval. These documents provide detailed descriptions of the boat across all disciplines: hull, piping, and electrical.

Advanced engineering methods, such as CFD (Computational Fluid Dynamics) for resistance estimation and FEM (Finite Element Method) for structural strength verification, may also be used.

Typical deliverables in the Detailed Design stage include:

Hull Discipline:

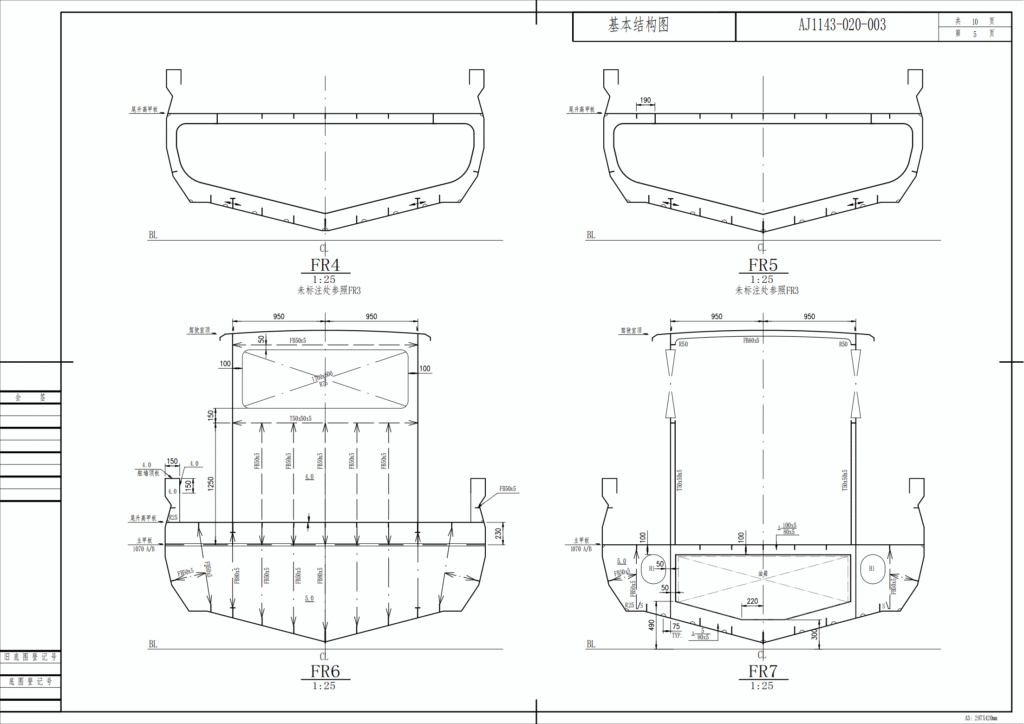

- Structural Drawings

- Structural Scantling Calculations

- Stability Calculations

- Life-Saving Appliance Arrangements

- Material Specifications

- Mooring Arrangements

- Weight and Center of Gravity Calculations (with breakdown)

- Welding Procedure Sequences

- Outfitting Arrangements

- Structural Strength Calculation Reports

Piping Discipline:

- Machinery Area Layout Drawings

- Compartment Ventilation Calculations

- Bilge Water Piping System Schematics

- Fuel Oil Piping System Schematics

- Machinery List

Electrical Discipline:

- Electrical Load Balance Calculations

- Electrical System Schematics

- Battery Capacity Calculations

- Electrical Equipment Layouts

- Communication/Signal System Schematics

- Communication/Signal Equipment Layouts

All drawings and documents are reviewed and approved by the relevant authorities, ensuring the safety and regulatory compliance of the boat design.

Production Design

The final stage is Production Design. During this phase, essential production information is extracted from the approved documents, and comprehensive shop drawings are generated for the shipyard. Since each shipyard may have specific requirements for these drawings, close communication between the design team and the shipyard is crucial to ensure the drawings meet their needs, thereby improving efficiency in both design and construction.

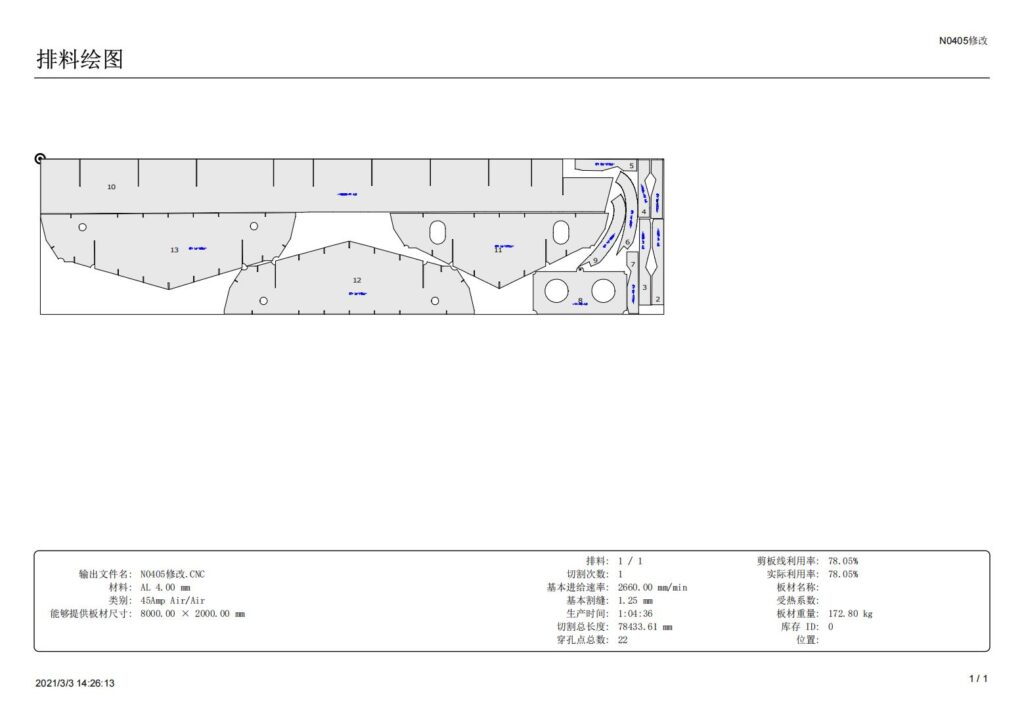

Production design primarily focuses on detailed structural drawings, including:

- Part Drawings

- Assembly Drawings

- Mold Frame Drawings

- Nesting Drawings

By following this structured boat design process, from concept to production, the likelihood of achieving a successful and well-constructed boat is greatly increased.